This feature is only available for subscribers. Subscriptions start from as little as 9.99.

Note: Currency and terminology may differ depending on your region.

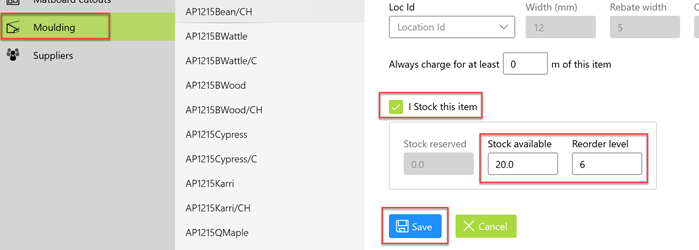

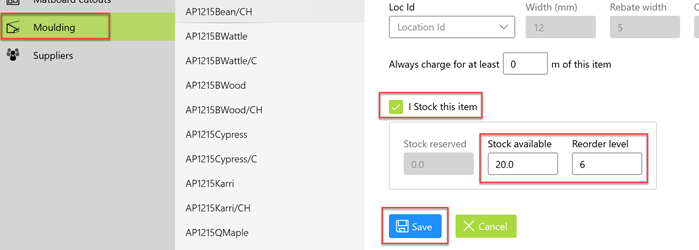

FramR allows stock control for Moulding and Items

Select the Moulding or Item and tick I stock this item, then enter the Stock amount and also a reorder level. The reorder level warns users if they have exceeded the minimum stock level when saving the Order. Click Save and your done.

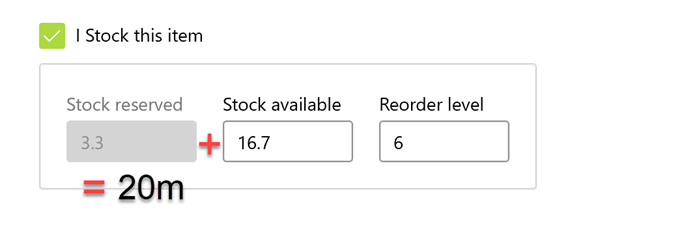

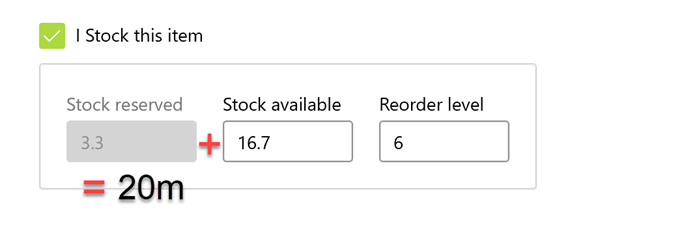

When a moulding or Item is added to a framing job and that job saved to an order, the quantity allocated for the job will be deducted from Available and recorded as Reserved. Meaning it is being held, waiting for the job to be completed.

The amount of moulding Reserved includes the overrun of the corners of the moulding, but it does not include the percentage allocation for Wastage.

When a job is marked as completed the material is considered used and both the reserved and stock level quantity will be adjusted.

If an item is added directly to an Order (not a framing job) this item is considered as collected

by the customer at the time of sale and not recorded as reserved. Both the Stock level and the Available amount will be reduced accordingly.

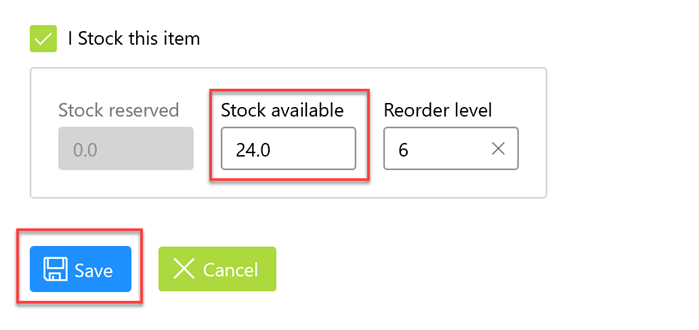

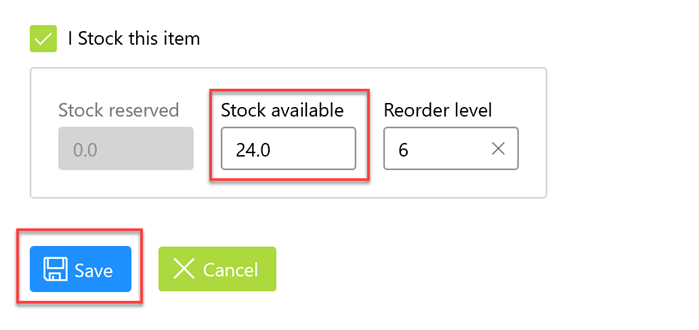

When new stock comes in the Stock Level can be adjusted on this form. For example; if the current stock level is 17.7 metres and 6 comes in, adjust the new level to 23.7 metres. It's

also at this point that adjustments can be made due to wastage. In this case 0.7 metres was deemed as wastage and deducted to make the actual Stock level 23 metres.

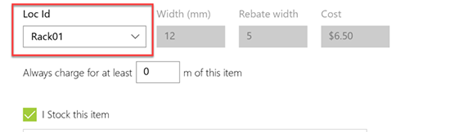

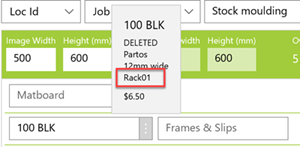

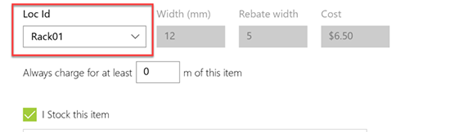

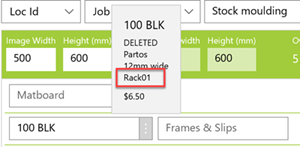

There is also a provision to allocate a Location Id (loc Id) to help maintain effeciency in your stock levels. The moulding Loc Id is displayed on the

Job form, Job sheet and Materials Required and Materials Used reports

Stock reports can be created to assess the total stock levels of all Moulding and Items. Only those Items marked as stocked will be displayed on these reports.

The Materials Required report collates all the materials required for a selected forthcoming period, helping to ensure you order everything you need for the jobs. You do not

need to be running Stock control to run this report, but it does report the stock level of Moulding and Items if you are.

FramR does not run stock control for other components as it is difficult to account for offcuts from sheet sizes and drop outs from matboards.